|

<< Click to Display Table of Contents >> Pulley Basic Design |

|

|

<< Click to Display Table of Contents >> Pulley Basic Design |

|

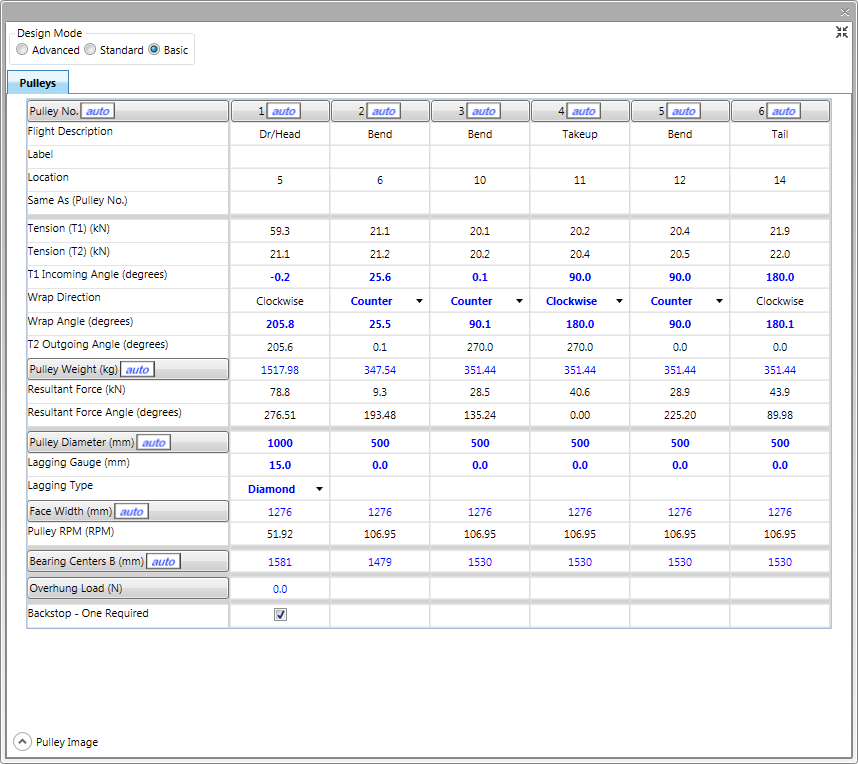

The Basic Input approach displays only the typical input data necessary for developing a pulley design -- T1 force and angle, T2 force and angle, pulley weight, resultant force and angle, pulley diameter, lagging, overhung loads, backstop.

Everything in blue is editable. Everything that is red indicates an out-of-spec condition.

The columns and rows headings including the ![]() button can be reset to automatic recalculation by clicking the button.

button can be reset to automatic recalculation by clicking the button.

•The Label is a user selected name or description for the pulley (limited to 12 characters).

•Pulleys can be designated as being the same as another pulley. Inputting the appropriate pulley number will make all the specifications the same and allow these specifications only to be changed on the indicated pulley.

This procedure allows the user to select "standardized" pulley specifications, limiting the number of different pulley specs on the conveyor.

•Tension T1 and Tension T2 are the calculated belt tension values multiplied by the Pulley Tension Multiplier.

The value for the Pulley Tension Multiplier is set in the Customizable Defaults Screen.

If the pulley tension multiplier is not 1.0, the value will be noted in the row heading for both the display and the report.

•The T1 Incoming Angle, Wrap Direction, Wrap Angle must be input.

For the resultant force to be accurately estimated, the T1 Incoming Angle and Wrap Angle must be input.

When changing the wrap angle for a drive pulley, the information in the drive data will also be changed.

•The Pulley Weight is estimated.

In the "Advance Design" method, the pulley weight can also be input by the user.

•The Resultant Force is the sum of the forces acting on the pulley.

In the "Basic Input" display, the pulley weight is not included in the calculation for Resultant Force.

•When automatically set, Pulley Diameter will be determined by the belt tensions, belt selection, and recommended minimum size for the belt, but also be at least three times the selected shaft diameter.

•The use of Lagging, its thickness and style are always user input. The use of lagging is indicated by entering a lagging thickness greater than zero.

The default lagging setting for drive pulleys can be set in the Defaults > Pulley page. Whether non-driven pulleys will be given the option for lagging in the "Auto" mode is also set in the Defaults screen.

When changing the lagging description for a drive pulley, the information in the drive data will also be changed.

•Face Width can be entered.

The default setting for pulley Face Width can be set in the Defaults > Pulley screen.

If appropriate, the user may enter data for an Overhung Load.

•The user may directly enter the shaft loading into the table. When the Overhung load is greater than zero, input for the location, Dimension C (distance of load from pulley bearing), and Angle of the overhung load are required.

The cells for entering data for the location and angle of the overhung load will not be visible if there is no overhung load.

•The user may utilize the Overhung Load Calculator to estimate the forces acting on the pulley shaft base on the drive configuration and design.

•If required, the backstop is automatically located on the head pulley and the required torque is displayed. However, this location can be changed (see Select Backstop).

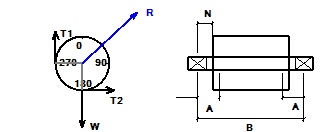

As the user scrolls across the columns from one pulley to the next, a sketch is provided for each pulley. The sketch is continually updated so the user can determine the effects of items such as T1 Incoming Angle and Wrap Direction. Sketches of each pulley are included in the printout.

The pulley sketch can be dragged to a position either below the specification table or to the right depending on the user's display preference.

See Also: Pulley Standard Design, Pulley Advanced Design