|

<< Click to Display Table of Contents >> Winch Off/On |

|

|

<< Click to Display Table of Contents >> Winch Off/On |

|

Available in All versions up to v19

Available in All

Updated in v19

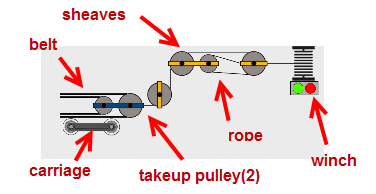

An semi-automatic take-up method where the take-up pulley is mounted on a horizontal trolley attached to a wire rope guided by a series of sheaves to an electrically (or hydraulically) powered winch. The tension in the belt is generated by an electric motor. The term "On/Off" means the motor only turns on when the belt tension exceeds a high/low tension dead band (sometimes referred to as a 2-possiton winch). When the motor is turned off (inactive), the brake is set and the take-up is "Fixed". Anytime the winch is off (inactive), all belt tension in the system will fluctuate as the take-up tensions range between the high and low dead band settings.

This option requires the smallest footprint and requires little vertical space. Can take advantage of mechanical sheaves to increase tension or increase travel therefore can be used on any conveyor length. if the dead band is set properly, the winch should not run very often but only adjust for permanent belt stretch and ambient temperature fluctuations which should result in low maintenance. On long conveyors, this option could be the least expensive option available and is always less costly than the "Always On" winch.

A fail-safe brake must be employed and in generally set. This device is generally the slowest option and therefore is not always able to keep up with transient conditions in the belt during stopping/starting. Therefore it is common to increase the dead band range during starting/stopping or keep the winch off (inactive) during starting/stopping. This generally increases system dynamics (increases all forces high and low) therefore advanced system design tools including flexible body transient analysis (dynamic analysis) is highly recommended when this option is chosen.

See Also: Fixed, Horizontal Gravity, Vertical Gravity, Winch Always On, Hydraulic