|

<< Click to Display Table of Contents >> Pipe Conveyor Power Calculations |

|

|

<< Click to Display Table of Contents >> Pipe Conveyor Power Calculations |

|

Available in v12.0 and higher

Available in Suite

Updated in v17.1

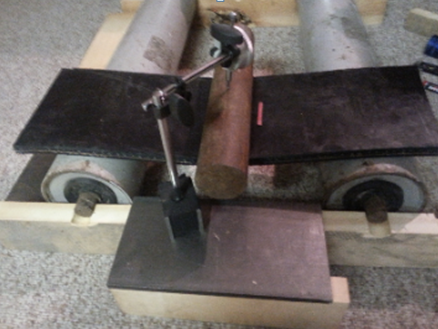

Pipe conveyors are similar to conventional troughed belts in that designs are belt sensitive. But pipe conveyors are more belt sensitive due to effects of transverse belt stiffness (Figure 1).

Figure 1

Although transverse belt stiffness is important to the belt manufacturer of a conventional conveyor in that the belt must be stiff enough to support the load and flexible enough to sit properly in the trough,it is not a consideration the conveyor designer has to worry about in a conventional conveyor design.

First,it has become clear over the last several years that it is very important for a pipe conveyor belt to always maintain good contact with all the rollers.

If the belt collapses and does not contact all the rolls as in Figure 2, it can result in belt twisting and rolling and perhaps not opening or discharging properly. Not only does gravity affect the pipe diameter but horizontal and vertical curves also exert forces that try to pull the belt away for the rollers. The transverse rigidity also decreases over time and repetitive belt flexing.

Figure 2

No current industry standard exists for what the proper transverse rigidly should be and it is left to the belt manufacturer to get this right. As some belt manufacturers have had problems with this in the past, they have all increased the transverse stiffness of their products.

However adding transverse stiffness has had an additional impact on the pipe conveyor designer in terms of power requirements.

Many analytical advances have been made in the design of conventional conveyors and the calculation of power (See CEMA 7th Edition power discussion) and all of these advances can also be applied to pipe conveyors however and additional consideration of transverse stiffness has been sound to be extremely important and has been overlooked by many.

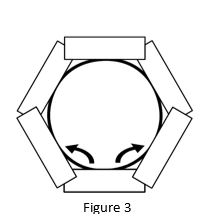

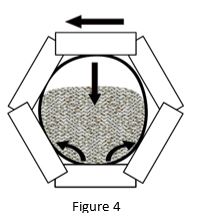

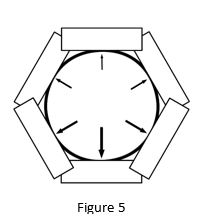

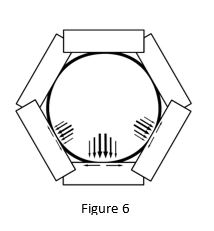

Since the belt is constrained in a pipe shape, the belt stiffness exerts additional forces on the idlers beyond the commonly known forces due to gravity and curves (Figures 3, 4, 5 and 6).

This mechanism of the belt “self-loading” the rollers actually requires a very different and quite complex analysis. Engineers have found this “self-loading” to be very significant. Therefore stiffer belts require more power even on an empty conveyor. It has been noted on many pipe conveyors in the field that empty and loaded power demand can sometimes show little difference

See also: Calculations, Indeterminate Analysis