|

<< Click to Display Table of Contents >> Belt Cover |

|

|

<< Click to Display Table of Contents >> Belt Cover |

|

Available in v14 and higher

Available in All versions, using CEMA 7th calculations

Updated in v19.1

The properties of the belt cover rubber can significantly impact the belt indentation drag. With the CEMA 7th calculation methodology, the user must select the approximate rubber type.

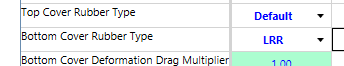

The type of belt cover rubber utilized is selected from a drop-down list of typical compounds on the Home > Belt > Belt > Data Table.

The generic choices for rubber compound are:

•Default

oIf you don’t know, use “Default” as it will cover all options

oIf you are using a Fire Resistant belt, use “Default”

•Good

oIf you are using a “Natural Rubber” based belt such as DIN X or RMA Grade 1, use “Good”

oIf you are using a high abrasion resistant compound from a major manufacturer, you can use “Good”

•LRR

oIf you are using a belt specially compounded for Low Rolling Resistance, you can probably use “LRR”

oIf you use “LRR”, you should always send a Belt Analyst printout to your Belt Manufacturer and ask them to verify their belt will meet the rubber indentation drag calculated for all cases…

▪Various Loads

▪Various Temperatures

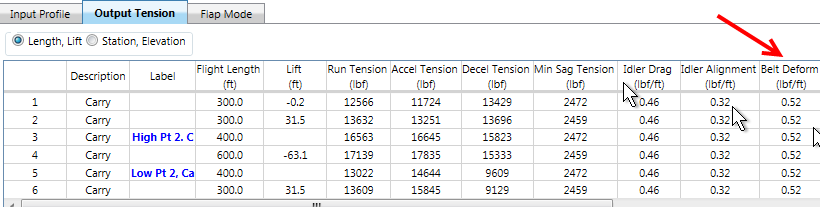

The resultant drag is shown on the Home > Profile > Output Tension Table.

Starting in version 19.1, Calculations performed with rubber data that does not come from the CEMA can be embedded into the belt analyst file so the results can be shared with other users who may not have the custom rubber file themselves. Rubber data that has been created with the small scale testing method (see testing link below) are designated with the "(SS)" symbol. Rubber data that has been created with the large scale testing method (see testing link below) are designated with the "(LS)" symbol.

The rubber constants used in the CEMA 7th calculation of belt indentation drag are shown if the Defaults > Belt > Rubber Constants screen.

For conveyors where belt indentation is a major contributor to drag, OCC recommends testing to confirm estimated values.

It is not possible at this time for users to directly enter belt indentation testing results into Belt Analyst. If this is wanted, contact OCC.

See Also: LRR Rubber Belting, Rubber Testing