|

<< Click to Display Table of Contents >> Rubber Testing |

|

|

<< Click to Display Table of Contents >> Rubber Testing |

|

For conveyors where belt indentation is a major contributor to drag, OCC recommends testing to confirm estimated values.

It is not possible at this time for users to directly enter belt indentation testing results into Belt Analyst. If this is wanted, contact OCC.

Dynamic Mechanical Analysis is a technique that can be used to study and characterize viscoelastic rubbers. . An oscillating force is applied to a sample of material and the resulting displacement of the sample is measured.

•Sample size is 3mm x 12mm x 30mm Rubber Only

•Test through Range of Frequencies

•Test through Range of Temperatures

•Test through Range of Strains

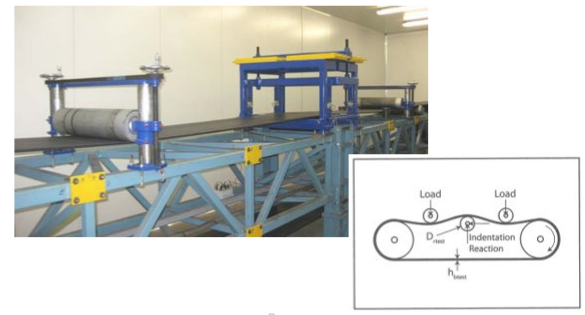

Test utilizes a full size belt running in a closed loop. Drag measured by instrumentation on a single idler.

•Sample size is full belt 350 mm wide by 4800 mm long (~1 ft x 16 ft)

•Test through Range of Frequencies

•Test through Range of Temperatures

•Test through Range of Strains

Many people like the large sample test as it measures actual values from actual belts, although testing can be expensive.

Using specialized test equipment, the indentation drag can be measured on existing conveyors.