|

<< Click to Display Table of Contents >> Bearing Grease Input Section |

|

|

<< Click to Display Table of Contents >> Bearing Grease Input Section |

|

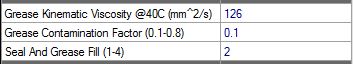

The highlighted section below contains information regarding bearing and seal grease within the idler for the calculation of its effect on drag and life of the bearing and seal of each roll.

The inputs for this section are described as follows:

•Grease kinematic viscosity – The viscosity of the grease used to lubricate the bearings has an effect on the estimated life of the bearing per skf and ISO 281:2007. The viscosity input here is used to calculate a life modification factor.

•Grease Contamination Factor – Per skf and ISO 281:2007 contamination within the grease also affects the fatigue life of bearings. This value is the ηC factor within the ISO calculation. Refer to skf or ISO:281:2007 for guidance on input for this value. Valid inputs are 0.1 to 0.8.

•Seal and Grease Fill – This input is used to define how much grease exists within the seal/bearing assembly. The more grease, the more drag there will be for each roll. Valid inputs are integers from 1 to 4 with 4 being extremely full and 1 being minimal grease fill.