|

<< Click to Display Table of Contents >> Feeder/Hopper Details |

|

|

<< Click to Display Table of Contents >> Feeder/Hopper Details |

|

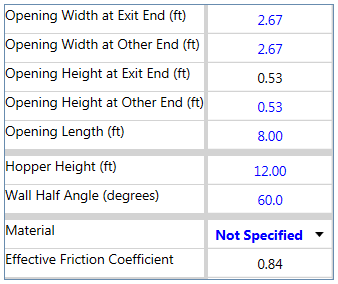

Use the spreadsheet to enter the hopper dimensions.

Everything in blue is editable.

The feeder/hopper design requires input data in a number of areas:

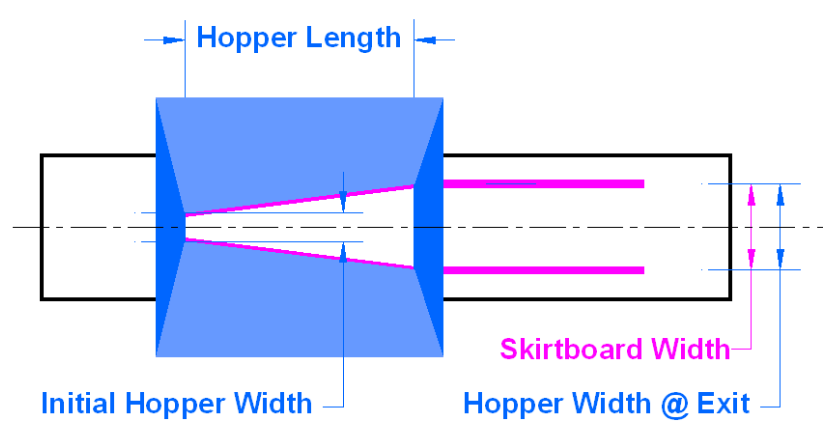

•The hopper opening is the shape of the bottom of the hopper over the belt. This is defined by "opening width at exit end", "opening width at other end" and "opening length".

A sketch of the hopper opening can be viewed in the display windows on the main screen. These dimensions will changed as they are entered in the spreadsheet.

A divergent opening improves uniform draw-down and a fully active outlet, as well as reducing skirtboard drag. A typical divergence angle is 3º to 5º, less for cases with large length/width ratios.

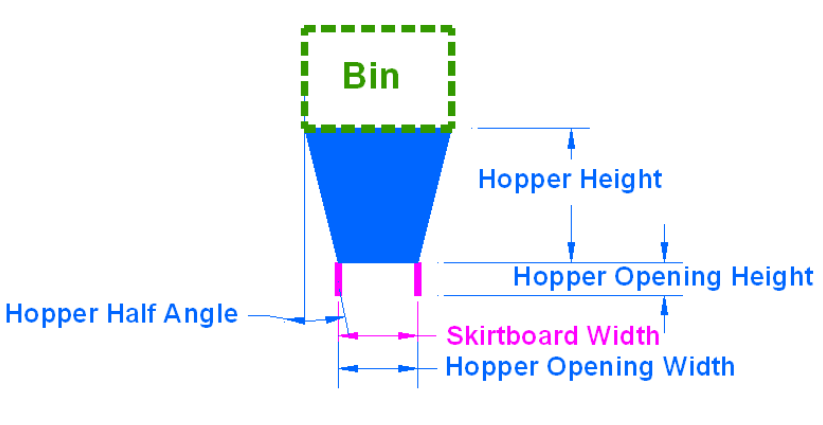

•The "hopper height" and "half-angle" of the hopper wall determine the shape of the hopper. In a rectangular hopper the end walls are assumed vertical.

It may improve material flow to have the hopper further from the belt at the discharge end.

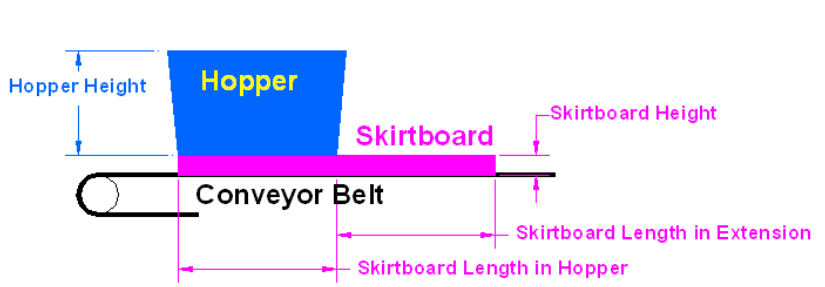

•The "hopper height at exit end" and "hopper height at other end" define the position of the hopper above the belt.

These also define the height of the skirtboard in the hopper section of the conveyor.

•The "hopper opening width at exit end" and the "hopper height at exit end" define the cross-sectional opening from the feeder to the conveyor. These dimensions, along with the material properties and belt speed determine the capacity of the feeder.

A sketch of the discharge opening can be viewed in the display windows on the main screen. These dimensions will changed as they are entered in the spreadsheet.

Generally, the opening width is about 1/2 the belt width. The opening height should be sufficiently larger than the largest particle size to prevent blockage, typically at least 1½ to 2 times.

•The hopper material will affect the material flow. The "wall friction angle" and "wall normal/vertical pressure ratio" should be entered.

See also: Shape Options