|

<< Click to Display Table of Contents >> Belt Data |

|

|

<< Click to Display Table of Contents >> Belt Data |

|

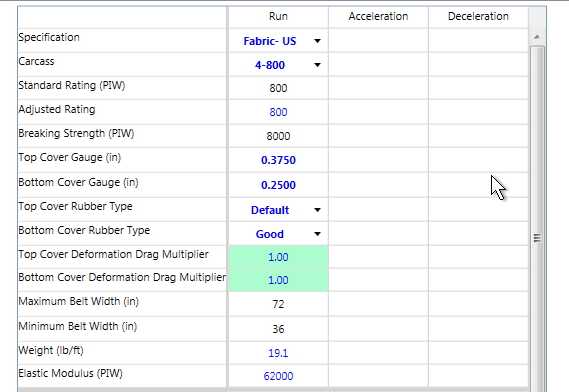

Auto DB, User DB or Custom mode is selected at the top.

![]()

•When the Auto DB mode is selected, the user selects the belt Specification database and the program selects the Carcass rating from the selected database.

•In the User DB mode, the user can select both the Specification and Carcass from the selected database.

•In the Custom mode, the user can/must input all the belt data without any reference to a database.

When reading a conveyor file, if the file belt data does not agree with the database information, the file data will be used and the selection identified as Custom.

Everything in blue is editable. Everything that is red indicates an out-of-spec condition.

•The Specification pull-down box contains the list of belt databases available on the computer.

•The Carcass is the description of the belt from the database. When in "User" mode this will be a pull-down box with a list of belts contained in the database.

•The Rating is the belt strength rating assigned in the database.

•The Safety/Design Factor is the ratio of the belt rating to its breaking strength.

In the PRO version of the program, in "User" mode the engineer can input a new Rating or Safety/Design Factor. These will be displayed as "Adjusted" values. Care must be taken when adjusting these belt specifications to make sure that the resultant belt is suitable for the application.

•Maximum and Minimum belt width information is accessed from the belt database.

•Top Cover Gauge and Bottom Cover Gauge must be input in all modes.

•For the CEMA 7 calculation method, the type of Belt Cover rubber utilized is selected from a drop-down list of typical compounds.

•The Belt Deformation Drag Multiplier is a factor used as a multiplier to the calculated belt deformation drag. This value can also be input in the Customized Defaults form. (This value will only be displayed and utilized if the friction calculation method is "CEMA 7").

Using a drag multiplier factor is an easy way to model a "low power" belt cover compound; a factor of 0.80 is typical.

If the conveyor has a belt turnover for the return side, only the bottom cover factor will be shown since it is the same for carry and return sides.

•The default Belt Weight is calculated from the users' cover gauge inputs and the carcass weight in the belt data base. This value can be input in the User DB and Custom modes.

•The default Elastic Modulus comes from the belt database. This value can be input in the User DB and Custom modes.

•The Apparent Length of the belt is estimated for the input profile data.

•The default Accel Rating comes from the Customized Defaults. This value can be input in all modes.

Two Design Modes are provided for analysis of the belt.

![]()

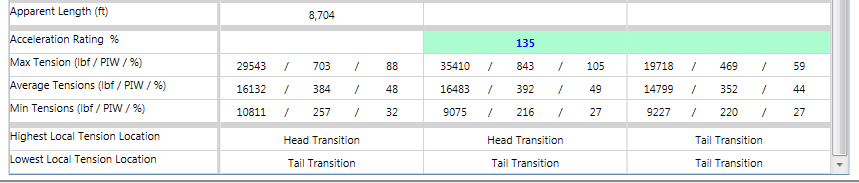

The standard mode allows for basic belt specification and outputs:

•Average, maximum and minimum belt tensions for running, accelerating and decelerating.

•Location of highest and lowest tension.

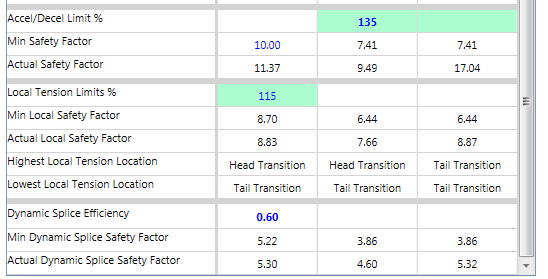

The Advanced design mode includes input for:

•Minimum acceptable safety factor,

•Accel/Decel Tension Limits as percent of belt rating,

•Local Tension Limits as percent of belt rating,

•Dynamic Splice Efficiency as percent of belt rating.

The displayed outputs are:

•Average, maximum and minimum belt safety factors for running, accelerating and decelerating.

•Location of highest and lowest tension.

•Average, maximum and minimum belt local safety factors for running, accelerating and decelerating.

•Actual and minimum splice safety factors for running, accelerating and decelerating.

See Also: Belt Database Considerations.