|

<< Click to Display Table of Contents >> Takeup Load Ratio Calculator |

|

|

<< Click to Display Table of Contents >> Takeup Load Ratio Calculator |

|

Available in v12 and higher

Available in Pro and higher

Updated in v18.1

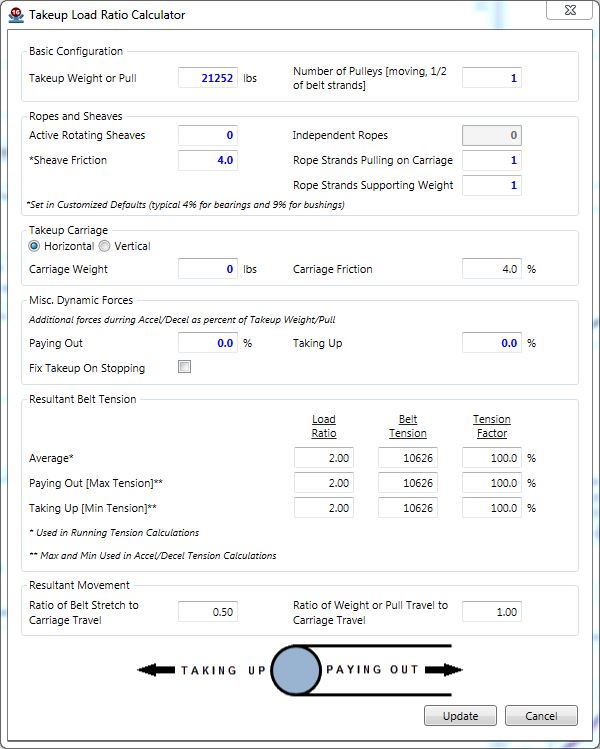

The Takeup Load Ratio Calculator is called by clicking the button in the Home > Takeup Tab or by clicking the 'Load Ratio [Weight-Pull/Belt Tension]' button on the takeup data table. This calculator is not applicable when a manual takeup is utilized.

![]()

The Takeup Load Ratio Calculator is used to estimate the affects friction inherent in the takeup design has on belt tension during starting and stopping. Several possible sources of friction in the takeup system are considered.

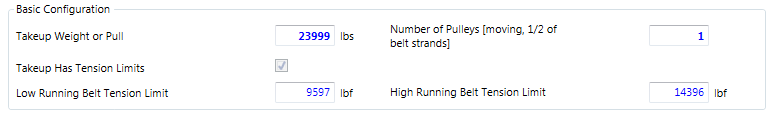

It is also utilized for entering high and low values for belt tension for those takeup devices, such as an off/on winch or hydraulic cylinders, that are off/fixed when the takeup tension is operating inside the defined tension band.

While friction will affect the system performance anytime the takeup is moving, only the impact on starting and stopping are considered in this calculation.

For an active system, the takeup weight is the pull exerted by the basic takeup device.

For an off/on type takeup system, the Low running Belt Tension Limit is the belt tension at which the takeup begins increasing pull. The High Running Belt Tension Limit is the belt tension at which the takeup begins decreasing pull.

A series of ropes and sheaves may connect the takeup pulley to the tensioning device -- weight, winch, etc..

•The program assumes there is one independent rope; if there are more, the user should enter the number of sheaves, rope strands at carriage, and rope strands at weight per independent rope. The number of ropes at each end of the system may affect the load ratio and the ratio of weight travel to carriage travel.

•Sheave Friction may be entered here, otherwise the value shown on the "Customized Defaults" screen will be utilized.

The takeup system may include a moving carriage. If it is horizontal, it's friction will impact the effective takeup tension.

•Carriage Weight can be entered by the user, or estimated by the program. To estimate the value, enter either a blank or "X" in the input box.

•Carriage Friction is assumed to be the same as sheave friction.

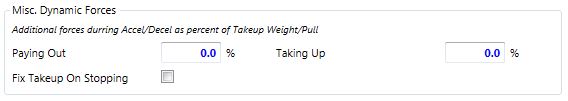

The takeup system may include other mechanisms that effect the forces while the takeup is moving.

•A Paying Out factor can be entered (as percent of takeup tension).

•A Taking Up factor can be entered (as percent of takeup tension, typically a negative value).

•Fix Takeup on Stopping lets the user controls the takeup to behave as manual takeup when the conveyor is stopping. To use this feature, simply check the box.

If belt tension increases for accel/decel then the belt is getting longer => Taking Up. Friction in the takeup system will decrease the actual takeup tension.

If belt tension decreases for accel/decel then the belt is getting shorter => Paying Out. Friction in the takeup system will increase the actual takeup tension.

•The Load Ratio is the ratio of weight or pull to the resultant belt tension.

•The Tension Factor is the amount (%) that the belt tension is affected by friction during acceleration and deceleration.

To exit this calculator:

•The Update Takeup button will transfer the data entered to the Takeup Tab -- Weight-Pull, Number of Pulleys, Load Ratio, Paying Out Tension Factor, and Taking Up Tension Factor.

•The Quit button will exit the calculator without updating the takeup data.

Some of the forces acting on the takeup can be tension, speed or time dependent such that this static analysis may not fully represent all the forces. In these cases, it is recommended that a dynamic simulation of the conveyor by made by a program such as Dynamic Analyst™.

See Also: Takeup Details