|

<< Click to Display Table of Contents >> Load On/Off |

|

|

<< Click to Display Table of Contents >> Load On/Off |

|

Available in v12 to v19

Available in All versions

Updated in v14.0

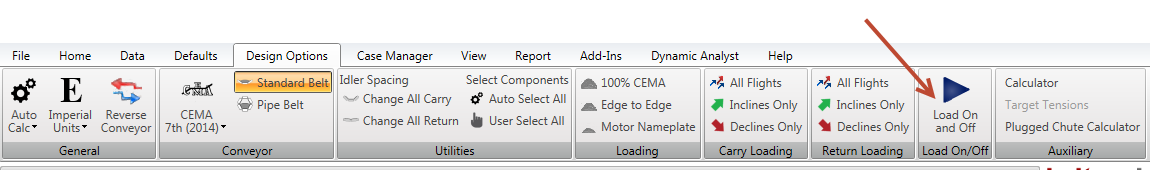

The Load On and Off sub menu is accessed from the Design Options > Load On/Off menu item or the Analysis > Load On/Off menu item.

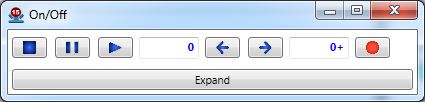

It activates a dialog box that initiates an automatic loading sequence where the conveyor loads on and then loads off at full capacity. The program completes all calculations for each successive loading step.

While the conveyor data can be viewed while cycling trough the load-on and load-off procedure, the input data can not be changed. The screen will show a "Read Only" label.

All tabs are temporarily set to User Mode (as opposed to Automatic Mode) during the "Load On and Off" sequence. At the end of the sequence, they are reset to the values initially set by the program user.

Since this procedure will change the conveyor loading on a flight segment by flight segment basis, the program may temporarily add some flight segments to somewhat level the flight segment lengths.

The user can choose either to automatically play through the loading and unloading procedure or step through it manually.

•Press the Play button to automatically progress trough the loading cases. The user can choose a lag time of none to ten between each successive load-on load-off sequence by entering the value in the Time Step box.

•Press one of the Step buttons, backward or forward, to manually step trough the load-on load-off sequence.

•The Pause button stops the automatic progress. After stopping, progress can be continued either automatically or manually.

•The Stop button ends the load on and off procedure and closes the toolbar.

A pull-down window allows the user to select additional load on and off procedures.

•Either the carry side of the conveyor or the return side, or both, can be included in the loading routines.

•The load on or load off sequence can be viewed individually.

•A single full block of loaded belt can be followed as it traverses the length of the conveyor. The size of the block is selected by the number of flight segments to be loaded.

•A single empty block on a loaded belt can be followed as it traverses the length of the conveyor. The size of the block is selected by the number of flight segments to be loaded.

•The automatic advancing through the load on and off routines can be halted if belt tension, power requirement or takeup requirement exceed an inputted threshold.

•The maximum and minimum calculated values for belt tension, power requirement and takeup requirement observed during the load on and off procedures can be recorded.

The values should be reset between different load on and off procedures.

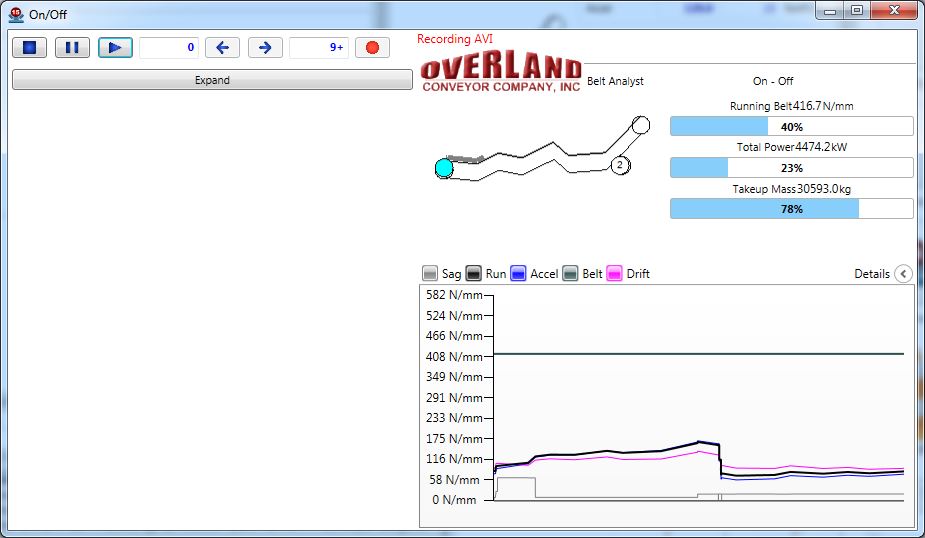

The animated load on and load off procedure can be saved to an "*.avi" file for reporting or presentation. This file will be saved in the data directory with the name of the conveyor file plus "-OnOff.avi".

1.From the control toolbar screen, click on the Record toolbar button.

2.The button background will be red when recording is activated and the main screen display will be modified to accommodate recording.

3.This will start the procedure for recording a screen movie. The program will take one picture for each step in the loading sequence.

4.Press the Play button to automatically progress trough the loading cases. The user can change the speed of the animation by using the Time Step box.

5.Press the Record button to stop the recording or the Stop button ends the load on and off procedure and closes the toolbar.